Mundan başga-da, SmCo magnitleriniň başga aýratynlyklary bar:

Ygtybarly öndürijilik: SmCo magnitleri demagnetizasiýa gaty çydamly, olary köp gurşawda ygtybarly edýär.

Poslama we okislenmä garşylyk: Birleşdirilen materialda demiriň azlygy sebäpli SmCo magnitleri poslama garşylygy gaty gowy.NdFeB-den tapawutlylykda, SmCo magnitlerine elektroplatasiýa gerek däl.

Temperaturanyň durnuklylygy: SmCo magnit güýjüni ýokary temperaturada (249-300 ℃) we gaty pes temperaturada (-232 keep) saklap biler.

Döwülen materiallar: Süzülende material döwük bolup biler, döwük we döwmek aňsat bolany üçin, gaýtadan işlemegiň çäklendirmeleri bar, adaty gaýtadan işlemegiň usullary işlemeýär.Şeýle-de bolsa, ýer bolup biler, ýöne diňe köp mukdarda sowadyjy ulanylsa.Munuň sebäbi sowadyjy, ýylylyk ýarylmagyndan we oksidlenen üweýji tozandan ýangyn howpuny azaldyp biler.

Goýmalar:

1. -okary derejeli PM hereketlendirijileri.Umumy PM hereketlendirijileri adatça ferrit magnitlerini ýa-da NdFeB magnitlerini ulanýarlar.Theöne temperatura 200 exceed-dan ýokary ýa-da duralga momenti uly bolan ýerlerde diňe SmCo PM hereketlendirijileri başarnykly.

2. endokary derejeli gatygepleýji ulgamlarda elektroakustiki enjamlar.

3. Ygtybarly gural ulgamy.Aerokosmosda, awiasiýada, lukmançylykda we beýleki ugurlarda ulanylýan köp gural, ýokary ygtybarlylygy we ajaýyp howpsuzlygy üpjün etmek üçin SmCo hemişelik magnitleri ulanmalydyr.

4. Örän möhüm radar we aragatnaşyk ulgamlarynda köp sanly syýahat tolkun turbalary, magnitler, kowalamak turbalary, kowalamak tolkun turbalary, girotronlar we beýleki elektrik vakuum enjamlary ulanylýar we SmCo magnitleri bellenilen ýolda hereket etmek üçin elektron şöhlelerini ýasaýarlar.

5. 3000 metrden aşak çuň guýularda SmCo magnit ekstraktorlary, 200 high ýokary temperatura gurşawynda SmCo magnit hereketlendiriji (nasos).

6. Magnit sorujy kellesi, magnit bölüji, magnit göteriji, NMR we ş.m.

SmCo Magnet baha sanawy

| Material | No | Br | Hcb | Hcj | (BH) iň ýokary | TC | TW | (Br) | Hcj | ||||

| T | |KG | KA / m | KOe | KA / m | KOe | KJ / m3 | MGOe | ℃ | ℃ | % ℃ | % ℃ | ||

| 1: 5 SmCo5 (Smpr) Co5 | YX-16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.050 | -0.30 |

| YX-18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-88 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.050 | -0.30 | |

| YX-20 | 0.90-0.d4 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.050 | -0.30 | |

| YX-22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-94 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.050 | -0.30 | |

| YX-24 | 0.96-1.00 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.050 | -0.30 | |

| 1: 5 SmCo5 | YX-16S | 0.79-0.84 | 7.9-8.4 | 612-660 | 7.7-83 | 30 1830 | ≥ 23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| YX-18S | 0.84-0.89 | 8.4-89 | 644-692 | 8.1-8.7 | 30 1830 | ≥ 23 | 135-151 | 17-19 | 750 | 250 | -0.040 | -0.28 | |

| YX-20S | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-92 | 30 1830 | ≥ 23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 | |

| YX-22S | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-95 | 30 1830 | ≥ 23 | 167-183 | 21-23 | 750 | 250 | -0.045 | -0.28 | |

| YX-24S | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | 30 1830 | ≥ 23 | 183-199 | 23-25 | 750 | 250 | -0.045 | -0.28 | |

| 1: 5 (SmGd) Co5 | LTc (YX-10) | 0.62-0.66 | 62-6.6 | 485-517 | 6.1-6.5 | 30 1830 | ≥ 23 | 75-8A | 9.5-11 | 750 | 300 | 20-100 ℃ + 0.0156% ℃ 100-200 ℃ + 0,0087% ℃ 200-300 ℃ + 0.0007% ℃ | |

| Ce (CoFeCu) 5 | YX-12 | 0.7Q-0.74 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

| Sm2 (CoFeCuZr) 17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥ 1990 | ≥ 25 | 175-191 | 22-24 | 800 | 350 | -0.025 | -0.20 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1990 | ≥ 25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1990 | ≥ 25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1990 | ≥ 25 | 220-240 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

| YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1990 | ≥ 25 | 230-255 | 29-32 | 800 | 350 | -0.035 | -0.20 | |

| YXG-22 | 0.93-0.97 | 9.3-97 | 676-740 | 8.5-93 | 53 1453 | ≥ 18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 87-9.6 | 33 1433 | ≥ 18 | 175-191 | 22-24 | 800 | 300 | -0.025 | -0.20 | |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | 33 1433 | ≥ 18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | 33 1433 | ≥ 18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | 53 1453 | ≥ 18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | 33 1433 | ≥ 18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0.025 | -0.20 | |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

| YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

| (SmEr) 2 (CoTM) 17 | LTC (YXG-22) | 0.94-0,98 | 9.4-9.8 | 668-716 | 8.4-9.0 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -50-25 ℃ + 0,005% ℃ 20-100 ℃ -0.008% ℃ 100-200 ℃ -0.008% ℃ 200-300 ℃ -0.011% ℃ | |

| Samarium Kobaltyň fiziki aýratynlyklary | ||

| Parametr | SmCo 1: 5 | SmCo 2:17 |

| Kýuri temperaturasy (℃) | 750 | 800 |

| Iň ýokary iş temperaturasy (℃ | 250 | 300 |

| Hv (MPa) | 450-500 | 550-600 |

| Dykyzlygy (g / cm³) | 8.3 | 8.4 |

| Br (% / ℃) temperatura koeffisiýenti | -0.05 | -0.035 |

| IHc-iň temperatura koeffisiýenti (% / ℃) | -0.3 | -0.2 |

| Dartyş güýji (N / mm) | 400 | 350 |

| Transvers döwmek güýji (N / mm) | 150-180 | 130-150 |

Arza

SmCo magnit howa giňişliginde, ýokary temperatura çydamly motorda, mikrotolkun enjamlarynda, aragatnaşykda, lukmançylyk enjamlarynda, gurallarda we metrlerde, dürli magnit geçiriji enjamlarda, datçiklerde, magnit prosessorlarynda, ses rulon hereketlendirijilerinde we ş.m. giňden ulanylýar.

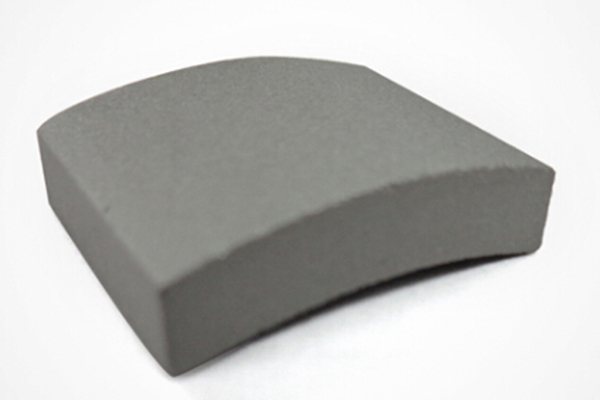

Surat ekrany